We still call it on-board training and we have to do some stuff there that not everybody enjoys alike. I speak about our projects. And how much of a pain it can be to draw if you are not able to. Especially if you don’t want to embarrass yourself too much.

During our training, we have to fill our On-Board Training Record Book. That alone can be a pain already. Sailors don’t seem to like paper work. Students, officers and captains seem to avoid filling that darned thing. And nobody knows why.

Mostly, there are easy tasks that the trainee has to fulfil and some officer has to check whether or not the student is able to master the task or not. And it’s really only ticking off some stuff. Such as understanding and using the Notice to Mariners or other maritime publications. Knowing where the ship’s copy of the SOLAS and MARPOL are. Easy things.

Very much of the rest, you’ll do by actually working on board. You know how to work aloft and use fall arresters and depending whether you do the engine training combined with the deck training or not, you even have the chance to tick off the same things four or five times in the two books in different places. It’s repetitive and sometimes boring. That’s one of the reasons, nobody seems to want to do it.

But there is one really tough nut. The projects. Somewhere on page 96 in the Training Book for Officers, there are the projects.

That’s where the real work starts and that must be what is what I’m most afraid of whenever I come to a new ship. Will I get the plans and drawings as a PDF? Or do I have to take pictures? Will photos be allowed at all?

And then the hours of drawing and describing mooring and cargo operations begin. Of course, many of us start too late. It’s work after hours and you usually want to relax after your watch, not do home work.

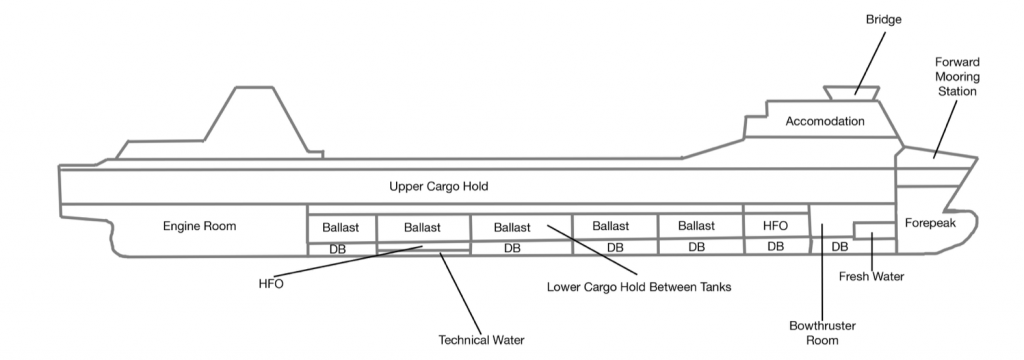

One annoying part of the plans is that you have to draw the same deck a couple of times. Once you do it for the allocated spaces, like cargo holds, offices, accommodation etc. And once you do it for all fire fighting and life saving equipment. And you do it for two decks.

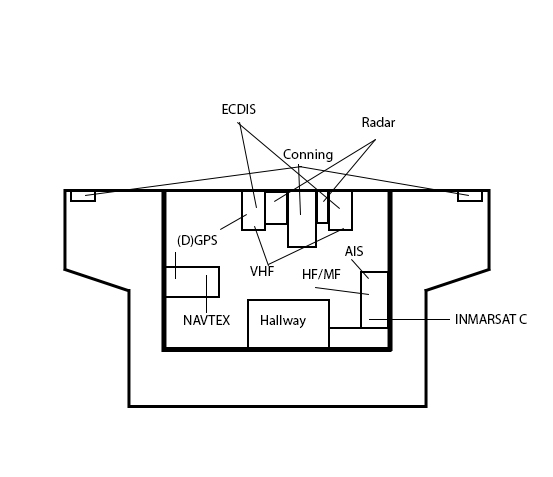

Additionally, you draw the bridge with all navigation equipment and the position thereof and you draw the mooring stations with their dangerous zones.

Finally, some diagrams of the pipeline system for the bilge, double bottom and other tanks have to be drawn and the used pumps explained. Did I mention that it’s a demanding task?

The worst thing of it all is, that when you are ready with it, nobody seems to care. I have experienced only one captain in my training that actually looked at the projects. And I doubt, anyone at school ever looks at them.

I know, it’s all about getting familiar with different types of ships and cargoes and it’s important that we know, what kind of safety equipment we find where on board, but it can be frustrating at times.

Leave your comment and join the discussion.